What exactly is the new TWINCULATORS software? How do software and hardware interact together and is it feasible with production planning? Mapping your production processes in real time – reality or vision?

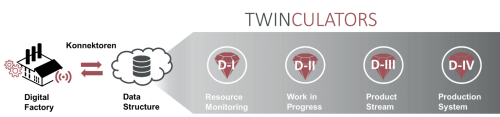

TWINCULATORS is a software solution of the scientific method of dynamic value stream analysis (DVSA). It is a cloud-based software that processes large amounts of data in real time and adapts itself scalable to the user’s production system. TWINCULATORS is based on production and production planning data, e.g. from sensor, ERP or MES data. The data is processed, synchronized and stored in a cloud through so-called connectors (see Fig. 1). As a result, the high effort for the preparation and synchronization of this data is eliminated. The four calculators and their analysis functions access this high-performance data. Thanks to the system architecture described above, it is possible to analyse your production independent of location, in real time and on any end device. In contrast to the classic value stream analysis, TWINCULATORS does not require time-consuming manual time studies, calculations and process analysis.

“In contrast to the classic value stream analysis, TWINCULATORS does not require time-consuming manual time studies, calculations and process analysis.”

The four modular calculators (D-I to D-IV) and their analysis functions can be easily configured by their operator. Thus, operators get an overview of the current status of processes, products and production systems in real time. As a result, planning and control are based on the actual situation on the shop floor.

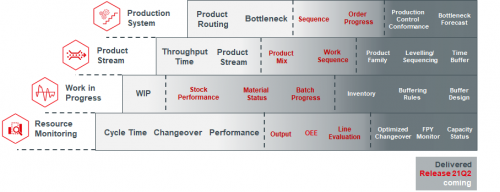

The Resource-Monitoring-Calculator forms the basis of TWINCULATORS (see Fig. 2). This calculator allows to display and analyse the current state of the production system by considering cycle and changeover times. It also provides information about the current performance of the production system. The Work-in-Progress-Calculator enables to monitor and analyse product-specific work in progress and process. In addition, Product-Stream-Calculator maps throughput time, compares it to cycle times and analyses production process variability. The Production-System-Calculator displays the distribution of the production volume regarding individual operating resources and enables the automatic identification of dynamic bottlenecks.

„The four modular calculators and the associated analysis functions can be easily configured by their operator.“

The architecture of the TWINCULATORS makes it possible to freely scale individual analysis functions in breadth of application (e.g. station, line, production area, production network) and depth of analysis (e.g. delivery points, zone analysis, parameter analysis). Thus, applications ranging from the analysis of cycle times of relevant individual stations to bottleneck analysis in flexibly linked production lines and output synchronization in production networks can be displayed and freely configured by the user.

Thanks to TWINCULATORS, real time mapping of production is no longer a vision, it is reality.

Kontakt

IPS Engineers GmbH

Joseph-von-Fraunhofer-Straße 20

D-44227 Dortmund

Telefon: +49 (231) 9700-711

Fax: +49 (231) 755-2649

E-Mail: info@ips-engineers.com

Aktuelle Beiträge

- TWINCULATORS Resource-Monitoring-Calculator – keeping an eye on the time

- TWINCULATORS Resource- Monitoring- Calculator – die Zeit im Blick behalten

- From management consultancy to software start-up – a leap forward in technology

- Functions and features of TWINCULATORS from a hardware and software perspective

- Funktionsweise der TWINCULATORS – hardware- und softwaretechnisch