Time as a critical success factor in development and planning projects is forcing many companies into new methods of project management and internal integration of engineering activities.

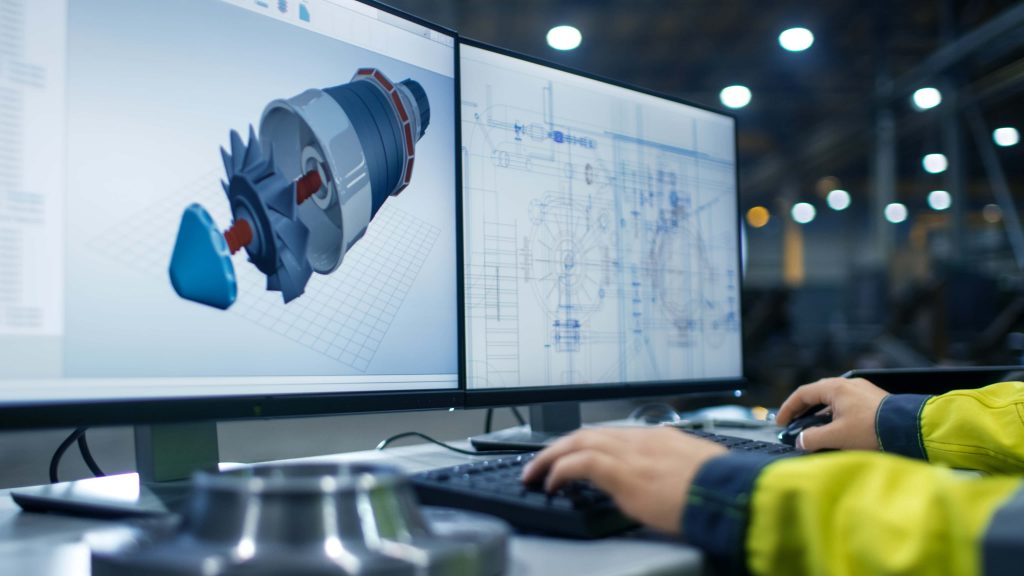

IPS Engineers adapts agile approaches for the development of complex production systems. In doing so, we use integrated and cross-company planning data management, to help you achieve cross-functional, capacity-optimized and time-optimized planning through simultaneous engineering.